Product overview

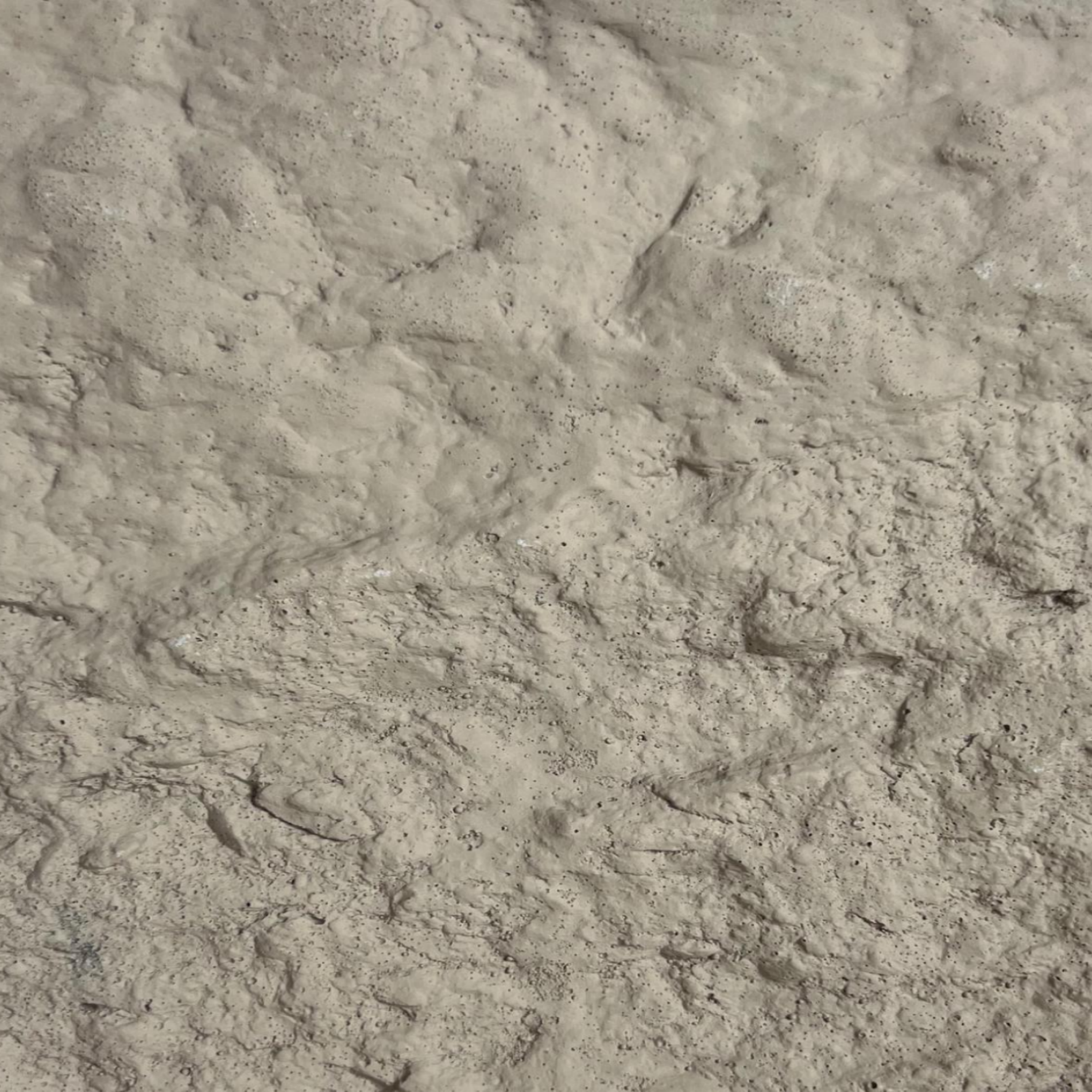

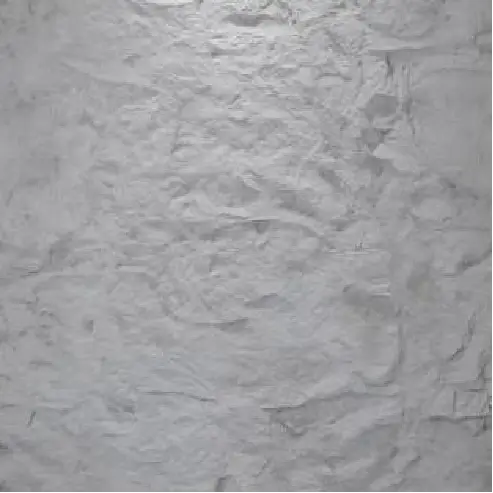

Art casting board series is a decorative plate made of high-performance fiber reinforced cement (FRC) as the base material, integrating natural mineral aggregate, inorganic pigment and polymer modifier, and through precision mold casting and surface treatment process. Products copy natural stone, wood grain, metal etching and other artistic texture, at the same time with lightweight, fire resistance, high durability and other characteristics. It is suitable for high-end commercial space, residential walls, art installations, public buildings and other fields, to achieve personalized design by industrial production, to meet the dual needs of aesthetic and functional modern architecture.

?

Purchasing Highlights:

?? Suitable for indoor and outdoor use.

?? Fire-proof and waterproof, moisture-proof and mildew-proof.

?? With a unique texture and color, can add a beauty and personality to the building, enhance the overall visual effect.?? Made of renewable materials, with the characteristics of environmental protection and sustainable, in line with the requirements of modern buildings for environmental protection.

?? Has excellent weather resistance, can withstand the influence of various climatic conditions, to ensure its long-term use effect.

?? Use the embedded back bolt or open hole to install the connection point, which simplifies the installation process and improves the construction efficiency.

?? Smooth surface, not easy to stain, easy to clean and maintain, can save later maintenance costs.

Construction guidance

1.Basic treatment: flat cement wall or wooden board as the base layer

2.Material processing: Cut and trim the board according to the size before installation; Grind the inner side of the external corner at a 45 ?X angle.

3.Installation on the wall: Use ceramic tile mastic for cement walls, structural adhesive/marble adhesive for woodworking board walls, evenly apply to the back of the board, and install the board on the wall; Nail the board tightly with wooden blocks/strips and remove it after the glue dries.

4.Gap repair: First fill the gap with the prepared sealant, and then dilute the color paste with a small amount of water for color repair.

5.Surface maintenance: After the construction is completed, the surface is sprayed with a finishing agent to prevent contamination

Catalog

购物车